How does stack effect work? See for yourself.

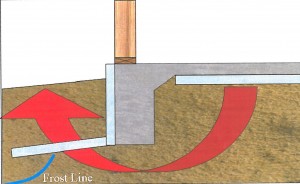

Stack effect (also called chimney effect) involves airflow into and out of a building caused by indoor and outdoor air temperature differences Everything starts with the fact that warm air rises and cold air sinks. In winter, your house acts much like a bubble of warm, buoyant air sitting on the bottom of a sea of cold, dense air. This creates a pressure difference, one of the key factors you need in order to have air flow. The actual distribution of pressures inside the house can vary, but generally the pressure is positive toward the top floors and ceiling (meaning air wants to escape outside) and negative towards the bottom floor (meaning air wants to come in). To complicate matters, a taller structure such as a multi-story house will contain a taller column of air that will produce greater pressure differences.

The other key factor allowing for airflow is a pathway for the air to move between the regions of differing pressures, which in your house means leaks in your building envelope. Things are fine if you have no air leaks, but even the tightest homes have some air leaks. As warm indoor air leaks through the walls or roof, it cools and deposits moisture along the way. The problems don’t necessarily stop there, however. New air to replace the air lost must come from somewhere. Replacement air will tend to take the path of least resistance. Typically air is drawn in through the lowest regions (the negative pressure zone) of the house, which is why problems with soils gases, such as radon, tend to increase in winter. Replacement air isn’t always just drawn in through the lower parts of the structure. Air can also infiltrate through poorly sealed or malfunctioning combustion appliances such as wood stoves and boilers, or plumbing traps that have dried out and are therefore no longer able to provide an air seal to the septic system.

The key to reducing potential problems with stack effect is good air sealing around penetrations in the building. If you are considering sealing air leaks in your house, it’s very important that you start at the top. If you start at the bottom, then you might be increasing the chances that air leaking out of the top will pull air from other sources such as combustion appliances. Some common air leakage points in the positive pressure zone of the house (if not properly air sealed) can include: can lights, chimneys, plumbing vents, wiring penetrations, bath fans, and range vents. Always be sure that you have a functioning carbon monoxide detector in your home and that your boiler and wood stove have a dedicated source of combustion air.