Windows can be a barometer for how much humidity is inside the home.

On really cold days, you may notice condensation forming on the inside of your windows. This can be caused by one or a combination of factors: excess humidity, inadequate ventilation, or poor windows. To understand and correct a particular issue in your home, you need to know some basic properties of moisture.

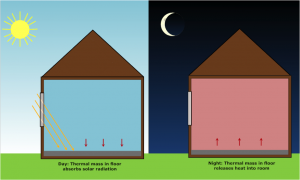

Condensation occurs when water vapor (a gas) turns into water droplets as it comes into contact with a cold surface. The point at which this happens (called the “dew point”) depends on the temperature and humidity of the inside air. The warmer the indoor air, the more water vapor it can “hold,” and moisture can better remain in the vapor state. When air moves next to a cold window, the temperature drops and it can’t “hold” as much vapor. That’s when you start to see condensation forming.

For example, if the indoor temperature is 70 degrees and the outdoor temperature is 0, then moisture will begin to condense on a single-pane window when there is roughly 15 percent relative humidity in the house. A double-pane window will cause condensation at around 25-40 percent relative humidity, and a triple-pane window at between 30-50 percent. These are rough numbers are based on average window insulation values.

The recommended indoor humidity levels for occupant health and comfort range from 30-50 percent. The general rule in a cold climate, however, is to target the lower end of this spectrum due to the risk of condensation within walls and ceilings. If your house has adequate mechanical ventilation, humidity is less of a concern. In Fairbanks, it’s tough to maintain anything close to 50 percent humidity in a properly ventilated house, because the winter air is so cold and dry. Because of its low moisture content, the inherent dryness of Fairbanks winter air is good for homes but not always the occupants, since the dryness can cause discomfort.

What can I do about it?

Three things: make sure your home is properly ventilated, aim for less than 40 percent relative humidity to keep both you and your home healthy, and consider replacing your windows or adding moveable window insulation during cold months.

If you already use mechanical ventilation and have low interior humidity, but are still having problems, you may need to examine your ventilation setting. If you have a heat recovery ventilator (HRV), it may be recirculating too often, which can contribute to increased moisture build up in the air. Recirculation mode closes the connection to the outside and brings exhaust air back into the rooms. Recirculation mode keeps the HRV core defrosted and saves energy, but sometimes it can run too long. Some experimentation with the HRV settings may be necessary. For example, in 20/40 mode the HRV brings in fresh air for 20 minutes and then recirculates for 40 minutes, and likewise for 30/30. If you’re getting condensation in your current mode, try decreasing the amount of time the unit recirculates.

Also make sure air is allowed to circulate—either passively or mechanically—throughout the entire house. If you close the door to the bedroom, the air can become cold and moist enough to condense on windows.

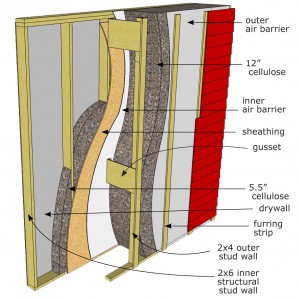

Older, poorer performing windows can create problems no matter what you do to your interior air. Bad seals around operable windows, metal spacers between the panes, and inadequate insulating value can cause the window surface to get cold enough for condensation to occur. If you’re not ready to invest in new windows, consider some type of moveable window insulation like foam board (on the outside) or well-sealed plastic film (on the inside). A CCHRC guide to different types of window insulation can be found at

http://www.cchrc.org/evaluating-window-insulation.