Takpaan Weber is a UAF student from Anaktuvuk Pass, a small Iñupiat village in the Alaska Brooks Range. She describes her experience working on the UAF Sustainable Village and other low-energy experimental prototype homes she has helped build in rural Alaska.

Tag Archives: University of Alaska Fairbanks

Sustainable Village Week 8

Framing is underway on the 4th and final house. Workers began applying ceiling vapor barriers and Grace rain and ice shields (which act as a drainage plane) to the fully framed homes. Now we’re exploring options for siding and interior finishing, looking at a combination of donated, market-value, and reclaimed materials.

Sustainable Village Week 6: trusses and T-shirts

During Week 6, we started framing the third (SE) house and laying out trusses for the two northern homes. Two more UAF students began working at the site for a total of four. The crew is jelling and construction is on schedule! It warmed up to 65 degrees this week, and the T-shirts and bug dope came out. Next week we are planning to finish roofs on the northern homes and begin plumbing and electrical work. Then we’ll add sheathing and trim. Meanwhile, we’ll begin framing the fourth and final house, which will likely have the Reina Wall–a double wall with thick blown-in cellulose insulation developed by local builder Thorsten Chlupp of Reina, LLC.

Framing, Floors & Slabs

We’ve made a lot of progress on the Sustainable Village this week—framed the first floor of the northwest house, started building the deck for the second floor, and poured concrete slabs for the two east homes.

The first floor of the first house was framed in a day. The 1,500-square-foot home has four bedrooms, a downstairs bathroom, upstairs kitchen, and big south-facing deck on the second story.

The beginning of the week was cold with scattered showers, so the concrete contractors waited until Thursday and Friday to pour slabs. The process took about two hours—the mixing truck and the pumping truck showed up and one of the guys poured the coloring (Santa Fe) into the mix. Then five guys worked together on the floor, spreading the “mud” from a rubber hose, moving it around with “mud sticks,” leveling the slab with a screed (or flat board), and smoothing and sealing it with a bull float (a long-handled tool with an aluminum float). Once the slab set up a bit, they went over it with a trowel (a flat, metal-bladed hand tool), which gets rid of any bumps and gives it a smooth finish. The slab is 1.5 inches with a pretty adobe color.

The crew is currently framing the second story. Next week students begin helping out on site.

- pouring the concrete slab for the southeast home

- radiant tubing within the concrete slab

- spreading the “mud”

- mixing truck pours cement into concrete pump

- pouring cement-a team operation!

- screeding, or leveling, the slab

- bull floating, or pushing the gravel to the bottom and the “cream” to the top

- smoothing and sealing the edges of the slab

- slab after 24 hours

Sustainable Village: Week 3 Timelapse

During Week 3, we built floors for the two homes on pilings and laid radiant floor tubing. The homes will have concrete slabs and and about 10 inches of under-floor spray foam insulation.

Spray Foaming the Foundations

Two of the homes will have insulated raft foundations. This allows the house to rest directly on the ground, keeping the floor warmer than if it were elevated on piles. A thick mat of spray foam is designed to prevent heat loss from affecting the frozen ground, and a cooling system was also installed in the gravel pad to chill the soils if needed.

Sustainable Village: Laying Foundations

CCHRC is demonstrating an innovative foundation design at the Sustainable Village. Two of the homes, sitting on permafrost about 9 feet deep, will be built on steel piles, a common method for building on frozen ground. The other two, situated on stabler soil, will have an insulated mat foundation.

Builders laid the mat foundations last week. They include a geotextile mat placed directly on the soil with several feet of gravel on top. PVC pipes are embedded in the gravel in a grid formation as a backup cooling system. Resting on the pad is a steel floor assembly. Spray foam was applied against the entire system for a monolithic layer of insulation at least 10 inches thick. This is designed to prevent heat from inside from transferring to the ground. Temperature sensors were strung about 10 feet down into the soil to monitor any changes. If needed, cold air could be circulated through the piping system in the winter to lower the temperature, as insurance against shifting ground.

Here’s a look at the pad preparation.

Groundbreaking for the UAF Sustainable Village

The UAF Sustainable Village broke ground on Friday, April 6 on lower campus near the Cold Climate Housing Research Center.

The development will feature innovations in cold climate construction—with super-insulated building envelopes to minimize heat demand—as well as experimental approaches to energy, ventilation and wastewater treatment. The homes will serve not just as student residences but also as housing prototypes, building science labs, and teaching tools.

UAF students helped CCHRC develop the concept for the homes, through a design contest, and will help build and conduct research on the Village as well.

“The thing that’s unique about this project is it’s engaging students for the first time in the development of sustainable housing,” said Michele Hébert, who heads the UAF Office of Sustainability. “Our hope is that this will lead to more young people learning how to live sustainably and be future leaders in sustainability.”

The 1,500-square-foot homes will have an R-50-60 envelope and will use a mix of solar, biomass and conventional fuel. A 14 kw photovoltaic array was funded by the university sustainability grant.

The project will demonstrate that a highly energy efficient 4-bedroom home can be built in Fairbanks without breaking the bank. The budget is approximately $200,000 per home. The rent will approximate the cost of a mortgage for an equivalent new single-family home in Fairbanks and be competitive with dorm rates.

Construction will be done by seasoned carpenters along with UAF student workers. Student residents move in in mid-August, so we will be busy for the next few months!

- A pile driver hammers hammers a steel round into the ground, part of the piling foundation.

- UAF Chancellor Brian Rogers describes what the Village means to the university community.

- UAF Sustainable Village breaks ground on April 6, 2012 next to the Cold Climate Housing Research Center

- CCHRC President Jack Hebert along with UAF Chancellor Brian Rogers share their goals for the Village.

- Lyle Axelarris participated in the student design competition and helped CCHRC design certain aspects of the Village.

- Students proposed ideas and concepts for the Village through a student design competition.

The UAF Sustainable Village: drilling, design, and detailing

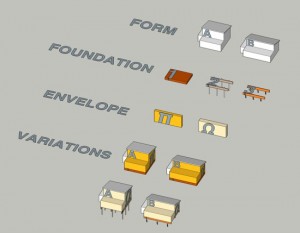

The University of Alaska Fairbanks (UAF) and the Cold Climate Housing Research Center are gearing up to break ground on the UAF Sustainable Village, a super-efficient campus housing project planned for this summer. CCHRC designers have developed the building form and floorplan as well as the envelope and foundation design.

Site clearing of four lots took place in November, and UAF scientists drilled two 30-foot boreholes for a soils analysis in February. The west site revealed strong, stable soils, with silt and gravelly sand, while the east site revealed marginal soils with six feet of silt and peat on top, then three feet of ice-rich silt, and below that fine sand and gravelly sand. “The east site will be the best place to test some innovative foundations,” said CCHRC designer Aaron Cooke.

Now the team is focused on structural engineering, construction detailing, and planning mechanical, electrical, plumbing, and other systems.

Meanwhile, students are involved in the project at many levels—creating cost analyses for renewable energy systems, helping CCHRC with the foundation design, and setting up a social study of the Village.

CCHRC Solicits Student Input for Sustainable Village at UAF

Aaron Cooke, architectural designer at the Cold Climate Housing Research Center, describes the goals of the UAF Sustainable Village and Student Design Competition.