We often stress proper ventilation as the key to maintaining a healthy indoor environment in a home, and promote heat recovery ventilators (or HRVs) as the best option for energy efficient ventilation in a cold climate.

We often stress proper ventilation as the key to maintaining a healthy indoor environment in a home, and promote heat recovery ventilators (or HRVs) as the best option for energy efficient ventilation in a cold climate.

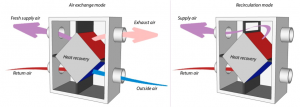

HRVs exchange stale indoor air with fresh outdoor air, capturing heat from the outgoing air to pre-heat incoming air. They exhaust excess humidity, carbon dioxide, and indoor pollutants from pet dander, cleaning supplies, offgassing furniture, and other sources. The role of the HRV becomes increasingly important as homes are built tighter to save energy, which cuts down on passive air exchange.

To maximize the benefits of having an HRV, it helps to understand the different operation modes. One of the often-debated modes included in most HRVs in the United States is the recirculation mode. This mode is not often used in Europe because it is believed that the health risks outweigh the energy benefits. This article provides a description of the recirculation mode and gives pros and cons for the house and its occupants.

Under normal operation, the HRV replaces moist indoor air with fresh outdoor air. While HRVs recover much of the energy from the heated air during winter months, a considerable amount of heat is still lost due to the frigid temperatures in the Interior Alaska. In addition, extremely cold outdoor air contains virtually no moisture, which can result in very low humidity levels indoors—a negative for some homeowners.

In recirculation mode, the unit closes the connection to the outside and brings the exhaust air back into the rooms. This saves a lot of energy, since there is no cold air coming in from outside. On the other hand, moisture and indoor pollutants are no longer being flushed out of the home, and their concentration will continue to rise and can eventually reach harmful levels. Recirculation can also spread unwanted smells from more to less polluted areas, such as from the bathroom to the living room.

In order to maintain sufficient air exchange, HRVs offer modes where these two strategies can be combined. For example, 20/40, 30/30, or Smart Mode. In 20/40, the HRV will bring in fresh air for 20 minutes and then recirculate for 40 minutes (likewise for 30/30). Smart modes usually require some kind of sensor (humidity or carbon dioxide) to dictate when to ventilate and when to recirculate, based on which measurements the HRV controller decides is more relevant at any given time.

The major advantage of recirculation mode is that it saves energy and redistributes heat throughout the house, particularly helpful if you have a localized heat source like a woodstove. On the flip side, it can potentially transfer pollution from one room to another rather than expelling it altogether. While Smart Mode seeks a happy medium between the two, there are still times when recirculation mode should not be used at all—if someone is cooking, smoking, or during times of high occupancy. One way to override the Smart Mode during these situations is with a push-button timer, a common feature of HRV installations that temporarily ventilates the HRV during such events.

If you do use recirculation mode, here are some best practices to maintain good air quality:

–High quality filters (High Efficiency Particulate Filters, HEPA, in combination with activated carbon filters) should be added to supply duct to mitigates odor or pollution from spreading

— Constant recirculation should only be used when the building is unoccupied

–If recirculation is used during occupied periods, make sure the HRV is exchanging indoor and outdoor air for at least part of every hour

While recirculation offers the perk of saving energy, if you rely on it too much, you can undermine the benefit of having an HRV—to maintain indoor air quality that is healthy for both humans and structures.